In the server mounting industry, there are two types of slide rails: ball bearing and dry slide. Originally, ball bearings were the most popular mechanism for slide rails, but as time went on, users gravitated towards dry slide. This is thanks to them being very cost effective (especially when purchased in bulk) with very little compromise.

Both options have their pros and cons, so we’ll break down our perspective.

Ball bearing slide rails

At face value, using ball bearings in a slide rail makes the most sense. There aren’t many people would prefer dragging metal on metal over the smooth slide experience that ball bearings offer.

But once you consider the costs, the frequency in which you will actually be sliding your rails and the fact that the mechanism is difficult to repair, it becomes a bit less appealing.

Some of our customers at RackSolutions swear by ball bearing rails, but even our larger customers with household names fill entire data centers with dry rails.

Ball bearing slide pros:

- Smooth slide

- 2 stage extension allows for access to cables

- No metal shavings

- No grease

Ball bearing slide cons:

- Less universal keyhole alignments

- Can break if twisted while removing

- Expensive

Dry slide rails

Nobody likes the sound of metal on metal, but dry slide rails are typically greased or lined with Mylar Tape. These solutions won’t last forever, but the rails themselves are rated to last even without added lubrication.

The most common fear that we hear about, regarding dry slide rails, is that metal shavings might infiltrate the server chassis. Through our testing and feedback from customers, we have yet to hear of this actually damaging any components. But, for peace of mind, simply dusting your server out with air would greatly reduce any minute risk of this happening.

Even though it is easier to design ball bearing slide rails with 2 stage extension, dry slide rails are able to be built so that users can pull the server out to reach cables. The compromise is that the rails stick out a bit further than the back post, where cable management equipment might be. Thankfully, this is possible to do without interfering with the cable management.

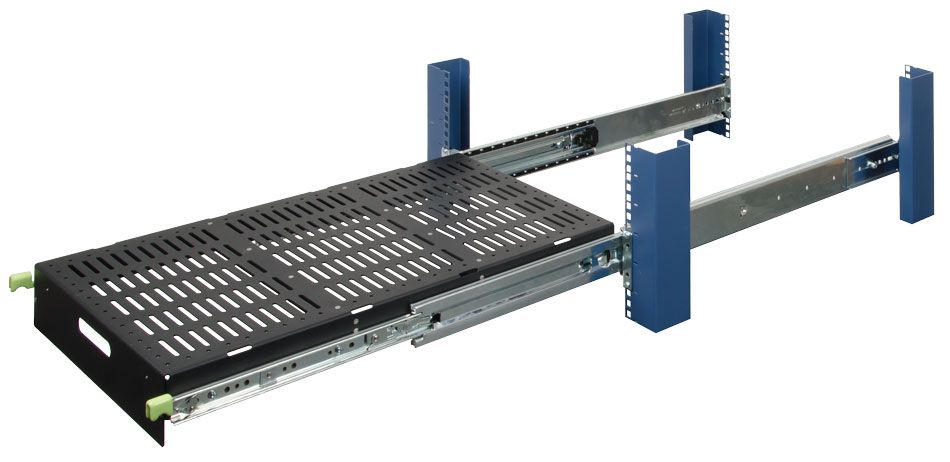

While as a company, we develop and promote dry slide rails for mounting servers, we do not not use the mechanism as frequently for sliding shelves. This is because we expect users to interact with shelves more often than rails.

Dry slide pros:

- Cost effectiveness

- Durability

- Easy access to cables

Dry slide cons:

- Not as smooth

- Use of grease

- Compromise for 2 stage extension