RoHS, TAA, and BABA are crucial regulatory standards that play a vital role for data centers and the IT industry. In this comprehensive guide, we’ll break down what each of these standards mean, why they matter, and how they impact business operations. These operations can be related to product compliance, trade, and manufacturing. Ultimately, understanding these regulations is essential for improving efficiency, ensuring compliance, and maintaining the integrity of your data center equipment.

What is RoHS?

RoHS stands for Restriction of Hazardous Substances, which is also known as Directive 2002/95/EC. This standard originated in the European Union and restricts the use of specific hazardous materials that are found in electrical and electronic products (EEE). All relevant products in the EU market must comply with RoHS regulations as of July 1, 2006. Currently, the RoHS Directive restricts the use of ten substances.

RoHS: Restricted Materials

The restricted materials under RoHS are: Lead (Pb), Mercury (Hg), Cadmium (Cd), Hexavalent chromium (CrVI), Polybrominated biphenyls (PBB), Polybrominated diphenyl ethers (PBDE), Bis(2-ethylhexyl) phthalate (DEHP), Butyl benzyl phthalate (BBP), Dibutyl phthalate (DBP), and Diisobutyl phthalate (DIBP).

Restriction of Hazardous Substances Directive

The RoHS Compliance is important because the restricted materials are harmful to the environment and pose occupational exposure risks during the manufacturing and recycling processes. With the RoHS Directive, these rules aim to reduce the amount of hazardous materials in electronic equipment. This helps to protect human health along with the environment. As a result, manufacturers, importers, and distributors of electrical and electronic equipment (EEE) are required to verify that their products comply with the RoHS Directive.

What is TAA?

TAA refers to the U.S Trade Agreements Act, which focuses on trade and product sourcing regulations. This compliance ensures that products are eligible for government contracts , meaning that the product itself must be made or “substantially transformed” in the U.S or a designated country. The primary goal of TAA is to promote fair trade and ensure that products used by the government are sourced from compliant countries rather than countries that are considered non-compliant.

Additionally, there are 3 different categories of TAA-compliant products:

- Domestic end products – made in the United States

- Designated country end products – made in a country that has a trade agreement with the United States (TAA Compliant products made outside of the U.S.)

- Foreign end products – made outside of the United States and do not meet the requirements for designated country end products

To achieve TAA compliance, a product must be made in the United States or a designated country,or it must have undergone significant changes in form, fit, or function within one of these locations. This particular process, referred to as substantial transformation, can be demonstrated by showing that at least 50% of the production took place in a TAA-approved country. Another way is showing that the modifications made in such a country were critical to the final product’s purpose and function.

What countries are TAA compliant?

The TAA outlines a list of designated countries that are TAA-compliant. These countries include Taiwan, Canada, Mexico, Australia, Japan, Germany, and several more. To see the complete list of TAA-compliant countries, it is available on the General Services Administration (GSA) website.

Being TAA compliant demonstrates a company’s commitment to ethical and responsible business practices. This helps to positively enhance a company’s reputation with customers, partners, and government agencies. Other benefits include eligibility for government contracts, reduced risk of penalties, access to global markets, and promoting fair trade practices. Overall, it allows companies to take advantage of the benefits and opportunities that come with complying with TAA regulations.

What is BABA?

BABA is known as Build America, Buy America, which is the process of ensuring that certain materials and products used in federally funded infrastructure projects are manufactured in the United States. The Build America Buy America Act, enacted as part of the Infrastructure Investment and Jobs Act on November 15, 2021. It established a domestic content procurement preference for all Federal financial assistance obligated for infrastructure projects after May 14, 2022.

This compliance encourages local production and ensures that government-funded infrastructure projects support domestic industries. The BABA requirements for federally funded projects are:

- Iron and Steel – all iron and steel items used in the projects must be produced in the U.S.

- Manufactured Products – all manufactured products must be made in the U.S. At least 55% of its component costs sourced domestically.

- Construction Materials – all construction materials must be manufactured in the U.S.

In conclusion, the BABA compliance promotes the purchase of domestic goods by giving preference to products made in the U.S for government procurement. BABA directly impacts the manufactured precast concrete industry, which provides essential infrastructure solutions across the U.S. If the product is not produced, mined or manufactured in the U.S, it is not BABA Compliant.

Conclusion: The Importance of RoHS, TAA, and BABA Compliance

In conclusion, RoHS, TAA, and BABA compliances are important regulatory standards that impact environmental and safety regulations, and product sourcing regulations, or local manufacturing and infrastructure. Together, these regulations not only enhance compliance and ethical standards, but it also fosters economic growth. This allows companies to remain competitive in a rapidly evolving global market. By adhering to these standards, companies will also be able to deliver high-quality products while contributing positively to the environment and society.

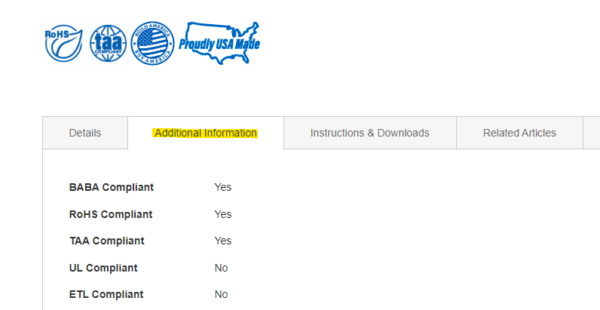

RackSolutions Compliance Badge

RoHS, TAA, and BABA are vital for data centers aiming to operate sustainably, legally, and competitively. This is especially crucial for businesses in an increasingly regulated industry. They are essential for environmental compliance, regulatory compliance, quality assurance, risk management, supply chain integrity, and market competitiveness.

To verify if a RackSolutions product is compliant with RoHS, TAA, or BABA, simply scroll down to the “Additional Information” tab on the product page. You’ll also find a badge indicating its compliance status. This makes it easier to identify products that meet these important regulatory standards.

For example, the Secure Wall Mount L09 for Lenovo Thunderbolt 4 Docking Station (SKU: 104-9109) features a RoHS, TAA, and BABA badge. This means the product is compliant with these standards.

RoHS, TAA, and BABA: FAQs

Why are RoHS, TAA, and BABA standards important for data centers?

RoHS, TAA, and BABA compliances play a crucial role in data centers and IT equipment. All three regulations ensure environmental compliance, regulatory adherence, and product quality. RoHS minimizes hazardous substances and promotes sustainability, while TAA and BABA ensure that the equipment meets with government procurement standards. As a result, adhering to these guidelines enhances operational efficiency, reduces risks associated with non-compliance, and improves market competitiveness. Ultimately, these compliances support the reliable and responsible operation of data centers.